The ideal AMR for frequent format changes and variable batch production

High-Mix Low-Volume (HMLV) manufacturing demands logistics solutions that can quickly adapt to constantly changing batches, with frequent format changes and operational reconfigurations.

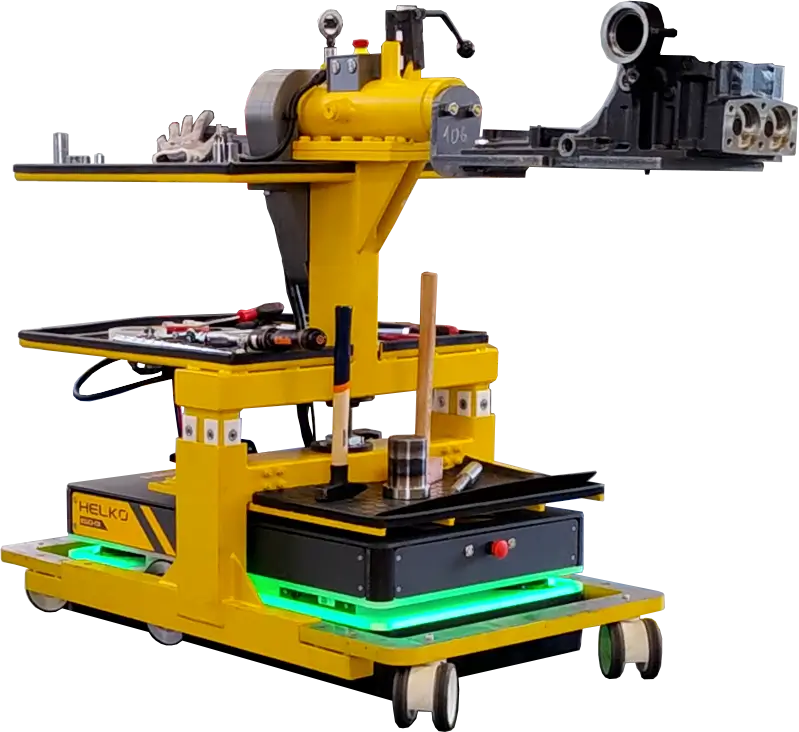

HELKO has been specifically designed for this purpose: an AMR capable of directly handling assembly stations, dynamically reconfiguring the line layout in real time according to active orders.

Thanks to its patented coupling system, HELKO can tow assembly stations directly.

The in-house developed NAVARCO software module centrally manages the fleet and integrates with existing enterprise management systems (MES, ERP, WMS) via RESTful APIs. This allows missions to be automatically generated in a Just-In-Time logic, or planned according to orders to be produced in the short, medium or long term, coordinating AMR movements based on actual production priorities.

The result is an adaptive internal logistics system that reconfigures the line layout according to the active batch, without modifying infrastructure or stopping production.

In more complex scenarios, TALOS comes into play: the AI-based intelligent planning module that analyses orders and manages the optimal production sequence, guiding the fleet based on delivery priorities, availability and workload balancing.

Customised AMR applications for

Custom automation and flexible assembly lines

- Automatic handling of workstations and components between stations

- Support for modular lines and reconfigurable layouts

- Reduction of downtime and waiting times between production stages

- Integration with MES and management systems for dynamic logistics

- Rapid reconfiguration of the assembly line based on the active batch

Optimisation of production flows

- Just-in-time transport of components or assembly kits.

- Dynamic movement of modular assembly stations and materials between workstations, ideal for plants where the layout frequently changes based on the order.

- AMR-driven handling of incomplete assemblies or finished products between testing, inspection, or final verification areas.

- Integration of the Mission Manager with the management system or MES to regulate production flows in real time and adapt to custom production priorities.

- Mobile assembly stations equipped with conveyors, special tools, or other interconnected devices.

Handling of workstations and wiring modules between workstations

- Autonomous transport of delicate components (wiring harnesses, electronic boards, etc.) between different assembly areas, reducing waiting times and risk of damage.

- Automatic movement of modular stations with wiring and components between assembly, soldering, testing, and configuration stations.

- Dynamic management of flexible production lines, where AMRs automatically reconfigure the layout by moving workstations and components according to orders, without interrupting the production flow.

Optimisation of production flows

- Just-in-time transport of components or assembly kits.

- Dynamic movement of modular assembly stations and materials between workstations, ideal for plants where the layout frequently changes based on the order.

- AMR-driven handling of incomplete assemblies or finished products between testing, inspection, or final verification areas.

- Integration of the Mission Manager with the management system or MES to regulate production flows in real time and adapt to custom production priorities.

- Mobile assembly stations equipped with conveyors, special tools, or other interconnected devices.

Handling of workstations and wiring modules between workstations

- Autonomous transport of delicate components (wiring harnesses, electronic boards, etc.) between different assembly areas, reducing waiting times and risk of damage.

- Automatic movement of modular stations with wiring and components between assembly, soldering, testing, and configuration stations.

- Dynamic management of flexible production lines, where AMRs automatically reconfigure the layout by moving workstations and components according to orders, without interrupting the production flow.

TALOS: Artificial Intelligence to reconfigure High-Mix Low-Volume production

HELKO doesn’t work alone. In high-variability applications, TALOS comes into play — the AMR and AI solution developed by Eureka System and Elif Lab within the European project EARASHI (Embodied AI/Robotics Applications for a Safe, Human-oriented Industry).

TALOS, acronym for Transformable Adaptive Lines Optimized System, is a manufacturing solution aimed at optimising traditional assembly operations by making production lines more dynamic and flexible. The project intends to replace fixed workstations with mobile workbenches managed by a fleet of autonomous mobile robots.

Within the EARASHI framework, Eureka System has created a High-Mix Low-Volume (HMLV) assembly line where:

- Workbenches are autonomously moved by HELKO AMRs,

- Production logic is driven by an AI-powered planner,

- The entire infrastructure is integrated into existing IT/OT company systems.

Thanks to this approach, companies can reconfigure their line layout in real time based on orders to be fulfilled.

TALOS employs constrained scheduling algorithms and Bayesian models to constantly adapt the production sequence, distribute workloads across workbenches, and optimise AMR routes according to priorities.

This represents the next level of logistics automation for Industry 5.0: flexible, adaptive, and truly integrated.

The TALOS project has indirectly received funding from the European Union’s Horizon Europe research and innovation action programme, via the EARASHI Open Call #2 issued and executed under the EARASHI project (Grant Agreement no. 101069994).

Would you like to transform your HMLV production?

Contact us: we will support you in designing a tailor-made AMR solution, customised to your actual operational constraints.

Contact us for a technical meeting