An intelligent planner for AMR missions, mobile assembly benches and production orders

TALOS is the module within the HELKO suite that brings artificial intelligence into dynamic production planning, with a dual purpose: to optimise the assignment of work orders in High-Mix Low-Volume (HMLV) environments and to coordinate AMR fleet movements in real time.

Developed in collaboration with partner company Elif Lab, TALOS integrates two interconnected algorithms:

- a constraint-based scheduling algorithm, which dynamically assigns work orders to AMRs based on active production tasks;

- a Bayesian model that learns from operational data and continuously refines parameters to improve task allocation, timing, and workload balancing.

TALOS enables advanced flexibility: assembly stations are no longer fixed, but modular and automatically reconfigurable by the AMRs, allowing rapid adaptation to changing production demands.

Tangible benefits for your production

Optimised lead times

More accurate AMR mission scheduling thanks to real-time knowledge of actual production times.

Real-time planning, even without a MES

TALOS's AI optimises workflow in real time, keeping stations synchronised and reducing delays caused by bottlenecks or misalignments.

Full integration with other systems

The AI calculates and suggests medium- and long-term mission planning based on real production and navigation data.

Reduced setup and reconfiguration times

TALOS dynamically reconfigures workstations in just a few minutes, minimising downtime due to line stops or product changes. The result: increased efficiency, even with variable lot sizes.

Balanced workload distribution

Optimised workload management to meet production and delivery deadlines.

Support for workforce well-being

Automatic detection of overloads, imbalances, and bottlenecks to support healthier, more sustainable work rhythms.

Continuous improvement

TALOS doesn't just generate a schedule — it learns from data and continuously improves over time.

An integrated module for mobile and flexible lines

TALOS is designed for production scenarios where the line is not fixed but dynamic — such as assembly processes served by mobile workbenches towed by AMRs.

In these configurations, optimisation requires a planner that takes into account not only the order to be executed, but also the real-time availability, position, and status of both robots and workbenches.

- Automatic generation of logistics missions based on the production plan.

- Just-in-time movement of AMRs to operators, arriving exactly where and when they’re needed.

- Integrated communication with the NAVARCO Fleet Management System for intelligent mission assignment.

- Ideal for reconfigurable layouts and flexible manufacturing environments.

Explore the full HELKO software suite

From mission planning to advanced fleet monitoring, HELKO is supported by a complete, modular, and fully integrable software suite.

Constraint-based scheduling

The AI planning algorithm processes active production orders and generates an optimised task schedule, taking into account multiple factors.

- Order priorities (by due date, type, or custom criteria).

- Characteristics of the carts or mobile workbenches.

- Load balancing strategies among the workbenches.

- Company-specific scheduling policies.

The planner can create complete or partial schedules, suggest modifications or cancellations of already assigned missions, and dynamically adapt to changes as they occur.

Adaptive Bayesian model

Built on real-world data from the production line, AMRs, and workbenches, the Bayesian model estimates key operational parameters:

- actual production time per unit;

- real-time performance of each workbench;

- optimal piece–bench–AMR assignments;

- battery status, robot speed, and workload;

- variations in productivity between tasks or operators.

These data-driven insights refine the scheduling output from TALOS, helping to prevent bottlenecks, reduce inefficiencies, and anticipate potential maintenance needs.

TALOS stemmed from the European EARASHI project

TALOS was developed by Eureka System and Elif Lab as part of the European EARASHI project – Embodied AI/Robotics Applications for a Safe, Human-oriented Industry.

The acronym TALOS stands for Transformable Adaptive Lines Optimized System. It is a manufacturing solution designed to optimise traditional assembly operations by making production lines more dynamic and flexible. The project aims to replace fixed workstations with mobile workbenches managed by a fleet of autonomous mobile robots (AMRs). A key innovation of TALOS is the optimisation of operations through dynamic planning of fleet movements using advanced algorithms and artificial intelligence.

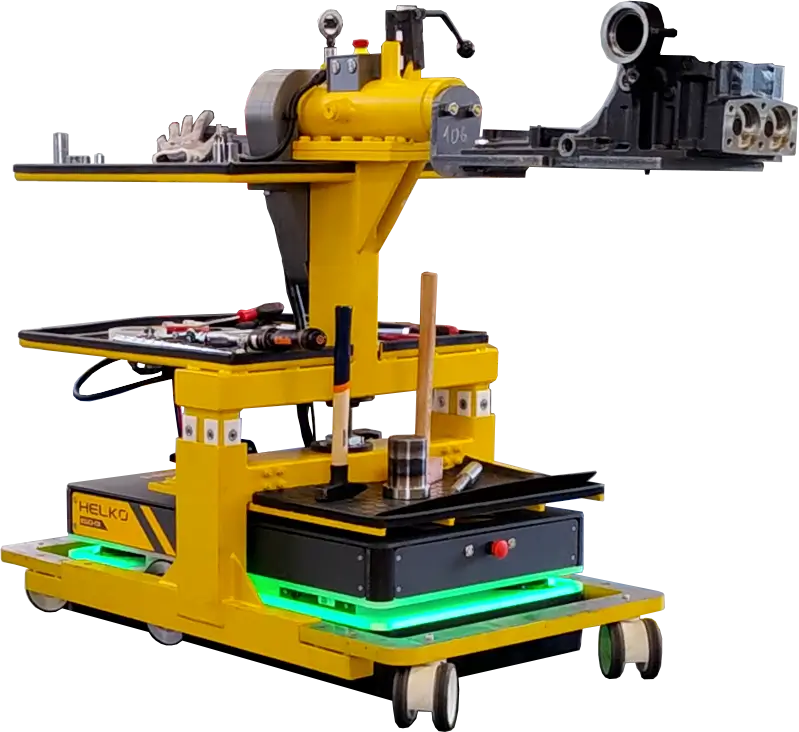

Within the EARASHI framework, Eureka System has already installed a High-Mix Low-Volume (HMLV) assembly line system featuring:

- mobile assembly benches transported by HELKO AMRs;

- an AI planner (TALOS) to optimise production and internal logistics;

- an integrated software infrastructure compatible with existing IT/OT systems, designed for real-world and scalable environments.

This solution utilises AMRs to transport individual workbenches, enabling the client company to “recreate” their assembly line in real time based on the specific operations required by each product type. Combined with a Mission Manager that plans production operations and AMR movements optimising them via AI, this technology offers an unprecedented level of production flexibility.

The TALOS project has indirectly received funding from the European Union’s Horizon Europe research and innovation action programme, via the EARASHI Open Call #2 issued and executed under the EARASHI project (Grant Agreement no. 101069994).

Do you have an idea or innovation need involving AI and AMRs?

Tell us about your business requirements – with HELKO, we can co-design a tailor-made mobile robotics solution.

Contact us for a tailored AMR solution