Your AMR, tailor-made

HELKO is more than just an Autonomous Mobile Robot (AMR); it is an advanced industrial handling solution tailored to fit perfectly with your company’s logistics flows.

Thanks to its modularity and full integration of hardware and software, HELKO transforms the concept of a mobile robot into a flexible and customisable platform, ideal for the needs of modern industry.

The hardware architecture is also fully customisable: it is selected for each application based on strict technical criteria and relies on standard electronic components available globally for at least 10 years. This choice ensures long-term reliability and operational continuity, even in high-intensity environments.

A Truck Robot designed to tow carts and workbenches

HELKO is a Truck Robot — a mobile drive unit designed to tow industrial carts and workbenches, adapting to complex production layouts, shared departments, and dynamic workflows.

Unlike many standard AMRs, HELKO does not carry the load on board: thanks to a patented mechanical system, it latches onto the cart, tows it along autonomously defined routes, and releases it at the destination. This approach enables flexible, modular, and configurable logistics without disrupting existing operations.

USAGE | Towing carts/workbenches |

DIMENSIONS | customisable to measure |

PAYLOAD | depending on application |

SPEED | 0.3 m/s ~ 1.5 m/s |

PROCESSOR | Intel Atom® |

A one-of-a-kind system

HELKO’s adaptive coupling technology detects the cart and attaches itself, adjusting to its exact position. Its strength lies in the patented side-coupling system — an exclusive technology that ensures:

- maximum load stability, even with heavy or irregular loads;

- optimal grip on floors that are not perfectly smooth or uniform.

The electrified coupling mechanism is also used for charging and can power the cart or load during navigation.

HELKO is the ideal solution for

- Line and warehouse logistics via AMRs

- Dynamic assembly lines with mobile workbenches

- Automatic replenishment and storage for assembly lines

- Cross-docking applications

- Tooling and machine set-up

- Removal of manufacturing waste

- Kitting and picking

An AMR built around your application

Every HELKO project starts from a simple premise: the application defines the machine. That’s why each HELKO is designed starting from your production, logistics, or ergonomic goals.

- Custom design, based on real operational requirements.

- Mechanical adaptation of the robot to fit the shape, structure, and dimensions of existing carts.

- Tailored logic for coupling, uncoupling, and navigation—especially in complex or variable layouts.

- Full flexibility, both hardware and software.

- Vertical integration: from robot development to software management, we handle every phase in-house.

Need an AMR with special dimensions? Or one that operates across multiple floors or maps? With HELKO, you get truly custom mobile robotics.

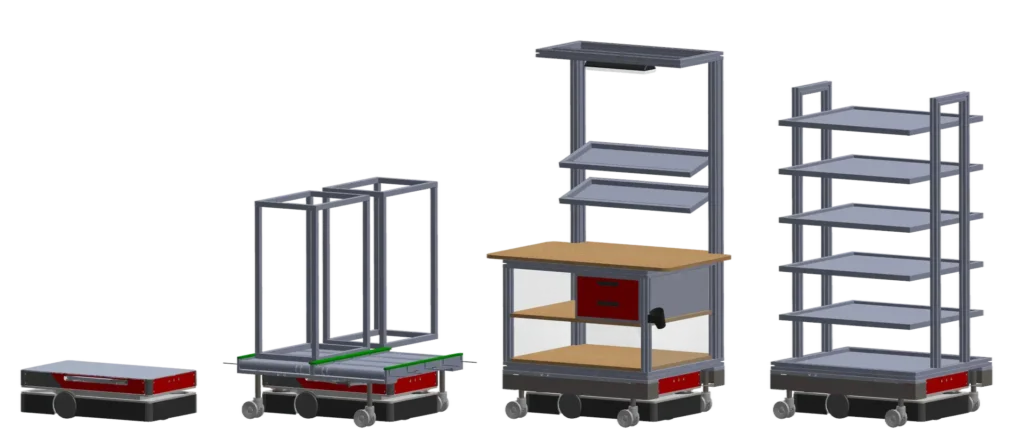

Modular Hardware

HELKO is designed and built in Italy with a robust, customisable mechanical structure, certified for industrial environments.

Autonomous Navigation

Multi-map and multi-floor autonomous navigation with active/passive safety management; obstacle detection; management of various types of areas and interaction points.

Single Applications and Fleets

Multiple types of missions can be assigned manually via a dedicated interface or automatically generated by third-party software using RESTful APIs.

Flexible IT Architecture

Various IT/OT architectures are supported, including Wi-Fi and 5G networks.

Software Integration

A flexible and scalable system offering interoperability with management systems (MES, MOM, SAP, ERP), machinery, conveyors, lifts, automatic doors, and more.

Comprehensive Support

Pre- and post-sales services: tailored integration; support in defining the map layout; staff training; specialist technical assistance.

Full Software Control

HELKO AMRs are equipped with a comprehensive and customisable software suite, developed by our in-house technical team.

Integration, Configurability and Customisation

HELKO is not an off-the-shelf AMR, but a mechatronic platform designed to be tailored and seamlessly integrated into the customer’s operational environment.

Its architecture is fully modular and customisable, both in hardware and software: we can configure dimensions, traction, the coupling system, sensors, carts, and operational behaviour according to the layout, logistics flows, and application requirements.

- Mechanical layout and aesthetic design configurable (footprint, height, speed, colours, visibility in sensitive environments).

- Powertrain, laser scanners, and other electronic components are selected based on technical specifications, industrial reliability, and a guarantee of global availability for at least 10 years.

- Custom-designed accessory hardware: simple or electrified carts, equipped with conveyors, sensors, or automatic loading/unloading systems.

- Possibility to integrate advanced sensors for cart recognition, load traceability, or operator identification.

- Interfaces with company software (MES, ERP, WMS) via RESTful APIs, OPC-UA, or SQL.

- Integration with existing systems: elevators, automatic doors, physical buttons, traffic light systems, RFID readers.

- Software (navigation, mapping, fleet management, AI…) is developed in-house and can be extended or modified to meet specific needs.

This design flexibility makes HELKO the ideal choice for complex facilities, dynamic environments, and non-standardised production, perfectly aligned with Industry 5.0 principles.

Autonomous Navigation Without Guides or Wiring

Ideal for transporting industrial carts or workbenches, HELKO excels in complex environments and dynamic production layouts.

To achieve this, it integrates an autonomous navigation system based on ROS 2, developed in collaboration with partner Proxima Robotics on the Proxima Compass platform, and fully integrated with the software suite developed by Eureka System. HELKO’s advanced navigation software maps the environment, enables the robot to orient and navigate within the mapped area without any aids or infrastructure, and ensures the AMR correctly identifies and couples with the cart even if it has been manually moved or roughly positioned.

HELKO features an advanced graphical interface for creating and managing navigation layouts — the Map Editor software module — which also supports multi-map and multi-floor installations. During the map creation process, all the rules and constraints that HELKO must respect during movement can be defined.

All AMRs in a HELKO installation continuously communicate with Navarco, the mission management software that monitors and coordinates individual robots and entire fleets in real time. Navarco assigns missions and their priority levels, controls interaction models with machines and personnel, and integrates with external systems (MES, ERP, WMS) to automatically generate missions based on production orders.

Thanks to laser scanning and continuous monitoring of real-time conditions, each HELKO can accurately locate its position, detect potential hazards, and respond with appropriate manoeuvres — from safe stopping to seeking alternative routes. On the IoT side, alarms, telemetry, and navigation data are fully accessible via a dedicated dashboard.

Key Features:

- Natural navigation system using Lidar for routine navigation and automatic environment recognition.

- Dynamic mapping and route definition through the Map Editor.

- Management of various mission types: point-to-point; multi-point with multiple load/unload destinations; cyclic missions; preferred missions.

- Obstacle detection and avoidance, including presence detection of people.

- Precise positioning system using high-intensity light clusters to optimise positioning, docking, and coupling operations.

- Automatic calculation of optimal routes.

- Real-time recalculation of alternative routes.

Certifications and Safety

Helko is a robotic system certified in compliance with the following standard safety regulations and directives for industrial environments:

- IP PROTECTION: IP40

- DIRECTIVES: 2006/42/EC; 2014/35/EU; 2014/30/EU

- STANDARDS: CEI EN 60204-1; UNI EN ISO 13849-1; CEI EN 62061; EN ISO 3691-4:2020

Moreover, thanks to its dynamic drive-cart coupling system, Helko ensures load stability throughout the entire journey.

Infinite Deployment Possibilities

Helko autonomously moves carts weighing up to 500 kg, transporting individual items or pallets along user-defined dynamic routes.

What makes it unique? Helko acts as a robotic drive, towing carts or workbenches; upon reaching the destination, it releases the cart and prepares for the next mission.

The range of cart configurations and customisations is virtually unlimited: from simple carts to drawer units, to workbenches for agile assembly lines. Moreover, thanks to autonomous navigation, transport missions can be carried out to and from any point within the indoor workspace.

Helko performs both GOODS-TO-PERSON missions and GOODS-TO-MACHINE missions, the latter managed through software interfacing with other machines or robots, requiring no human interaction.

Standard type of movement: coupling and towing industrial carts, assembly benches, or workstations.

Transportable load: up to 500 kg

Maximum speed: 1.5 m/s at full load

Floor depressions or steps: up to 10 mm

Floor gaps: up to 15 mm

Operational Autonomy and Fleet Energy Management

HELKO is designed to ensure maximum operational uptime even across multiple shifts, thanks to optimised power consumption settings and an intelligent energy management system.

Its autonomy reaches up to 16 hours of continuous operation (duty cycle 60%)*, with fully automated charging management.

The battery charge status of each robot is software-managed to estimate remaining autonomy as accurately as possible, automatically dispatching charging missions when urgently required.

An integrated Battery Management System (BMS) within NAVARCO monitors the fleet’s charge status in real time, coordinates charging missions, and manages operational priorities. The result is autonomous, continuous logistics without unplanned interruptions, even in high-intensity production environments.

In advanced applications, specific AI algorithms or the TALOS module itself can activate predictive charging strategies, optimising AMR utilisation based on expected workload, energy status, and order sequencing.

Batteries: LiFePO4 48VDC (LFP) or LiNiMnCoO2 48VDC (NMC)

* Battery life estimates are approximate and based on benchmark test results that measure battery life in various application contexts. Actual battery life depends on various factors, including configuration, load, and robot usage. Maximum battery capacity tends to decrease over time and with use.

Technical Support and Tailored Integration

Specialised pre- and post-sales services: we provide support at every stage of the project, from the initial environment mapping to assistance in defining the route layout, through to turnkey commissioning.

Complete integration with your existing IT/OT infrastructure: we analyse your specific application case and configure the AMR system to integrate with management software (MES, ERP, WMS), plant equipment, and field devices.

Operational training and ongoing support: technical training for personnel, with specialist remote or on-site assistance, even for multi-shift or multi-site facilities.

Remote control and real-time diagnostics: every HELKO is equipped with a web/mobile interface that allows remote monitoring and intervention, as well as direct submission of support requests to the first-level technical support team.

*Intel, the Intel logo, and Intel Atom are trademarks of Intel Corporation or its subsidiaries.

Do you have an idea or innovation need involving AMRs?

Tell us about your business requirements: with HELKO, we can design a fully tailored AMR solution together.

Contact us for a tailored AMR solution